Chinese manufacturing isn’t just about assembly lines; it’s about the magic that happens before components reach their final stage. This magic is injection mold china and aluminum die casting, two processes that transform raw materials into specific parts like alchemists.

Injection Molding: The Architect of Accuracy

Think of molten plastic as a vibrant liquid being injected at high pressure into an intricately designed mold. That mold acts as a blueprint because it is actually a negative copy of what is desired. As the material cools down and solidifies within, it takes up its shape in very fine detail. This allows for complex designs with thin walls necessary for some plastic parts to be produced such as those found in car dashboards or sleek phone cases or even colorful building blocks which could spark any child’s creativity.

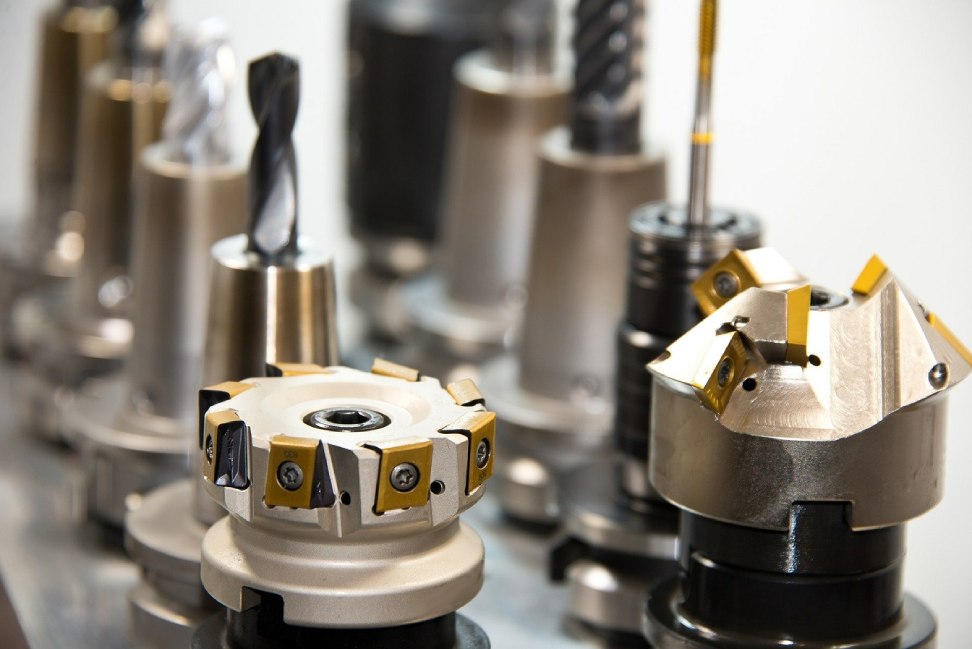

Aluminum Die Casting: The Sculptor of Strengths

Imagine silver torrential streams made up of molten aluminum alloy flowing under high pressure into reusable metallic molds. These molds are then filled by this fast stream so that they get occupied by the still liquefied metal before hardening sets in almost instantly afterward thereby creating very smooth finishes on these components whose strength is also quite remarkable when compared against other methods used during casting processes like sand casting which takes more time but produces rougher surfaces instead . This technique can therefore be likened unto sculptors shaping strong yet lightweight aluminum die casting manufacturer items mainly used where there needs weight saving such as bicycle frames for top range bikes or aircraft parts meant to fly higher than ever before while defying gravity easily along with others.

Metamorphosis Of Matter

Which process to choose depends on what one wants achieve at end product level; if you require something colorful and intricate for instance toys then injection molding would do best but when need arises for strong yet light weight component say vehicle part then aluminum die-casting becomes most appropriate solution considering its capability in delivering close to net shape features with good mechanical properties where required . Understanding this transformation is therefore key here as injected plastics are made up different types known as thermoplastics each having their own unique characteristics whereas castings involve use of corrosion resistant metals like those based on zinc which offers excellent electrical conductivity but low cost among others such aluminum being one them also

China: Land Of Industrial Magic

The reason behind china’s success in these procedures lies not only within its infrastructural foundations but also due to the large number skilled laborers it has been able attract over years thus leading into availability cheap yet highly qualified workforce capable handling any type job requirement thrown at them plus easy access modern equipment needed for carrying out various functions involved during production stage since everything required can be conveniently sourced from local suppliers without having rely too much on imports which might result into increased costs or delays associated with transportation timeframes. Nevertheless, caution should be taken when choosing partners so as to ensure that only those manufacturers who specialize particular industries are engaged upon while putting stringent quality checks together clear lines of communication will serve well towards achieving desired results through successful collaborations between parties involved.

By explaining injection molding and aluminum die casting you get the power over China’s manufacturing alchemy for your project. Selecting a process can help you see your vision come true, whether it is a complex plastic masterpiece or a lightweight strong aluminum marvel.

Summary

Injection molding and Aluminum Die Casting are what make manufacturing in China magical. This is achieved by converting raw materials into precise parts.

Injection Molding: The precision architect shapes molten plastic with high pressure into complex designs and thin walls that are suitable for car parts, electronic casings among other things made from plastics. It can use a wide range of thermoplastics.

Aluminum Die Casting: The strength sculptor injects molten aluminum alloy into a mold to create lightweight but strong pieces used mostly where weight matters like aircraft components or top-end bicycles. In this case Aluminum alloys have an upper hand.

Which process should you choose? Intricate plastic parts or strong lightweight aluminum components?

Frequently Asked Questions

Q: Why should one manufacture injection molds or aluminum die casting molds in China?

A: There is competitive pricing due to established infrastructure and many experienced manufacturers.

Access to advanced technology

Efficient scaling of production capabilities

Q: What factors should I consider when choosing a Chinese injection molding or aluminum die casting manufacturer?

A: Experience within your industry

Quality control measures being followed through by the company selected

Clear lines of communication during the project period between all parties involved

Q: Which is cheaper; Injection Molding Process Vs Aluminum Die Casting Process?A: Both processes have significant upfront mold costs, however for high volume productions of plastic parts lower material cost makes injection molding more cost effective as compared with aluminum.

Also Read:

- What Is PCPartpicker?

- What Is Facebook Protect?

- How To Redeem Roblox Gift Card?

- How Often Does Lenovo Outlet Update?

- Dell Optiplex 790 – Overview, Specification, Price